- This topic has 11 replies, 4 voices, and was last updated 2 years, 6 months ago by .

-

Topic

-

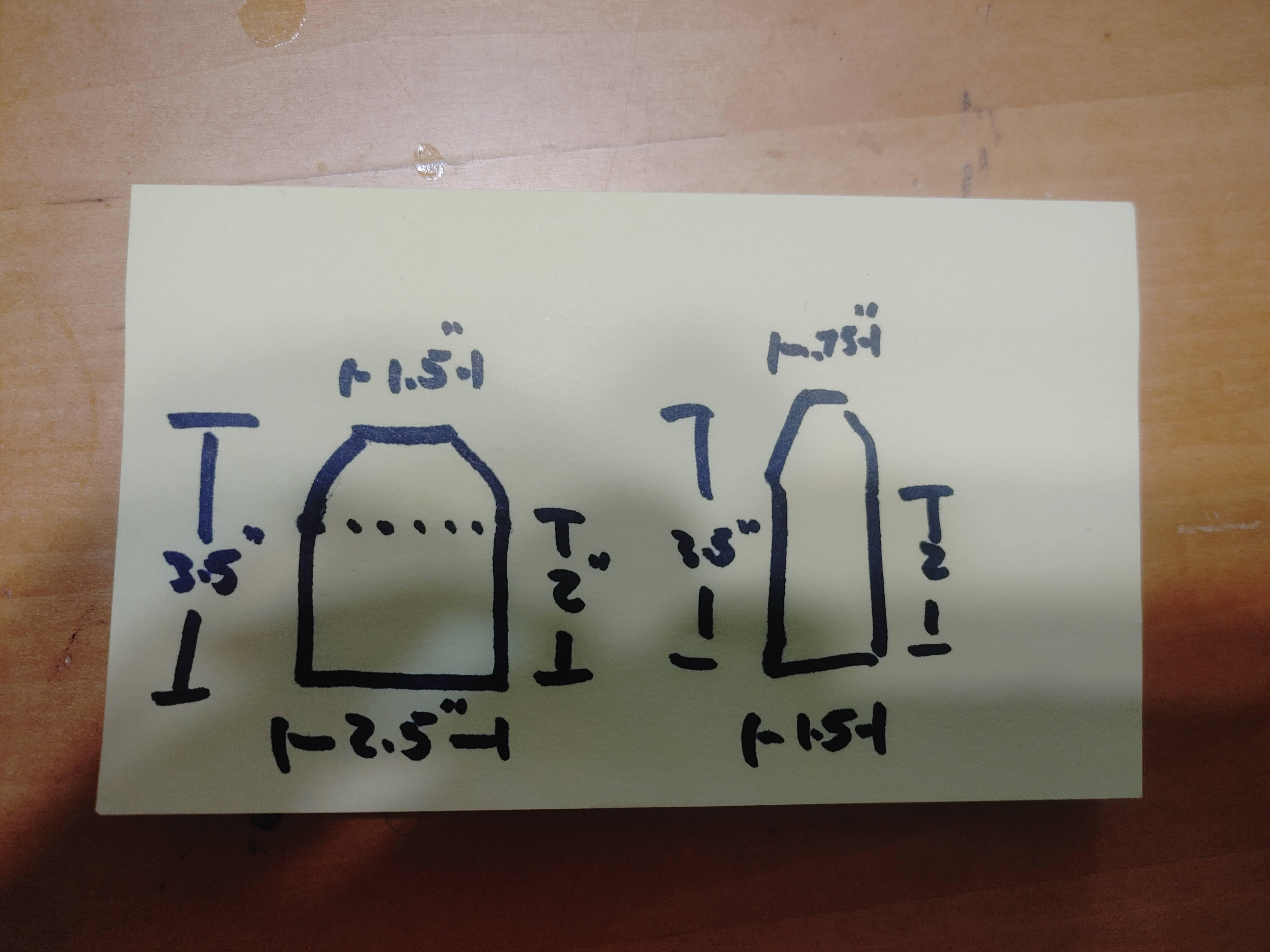

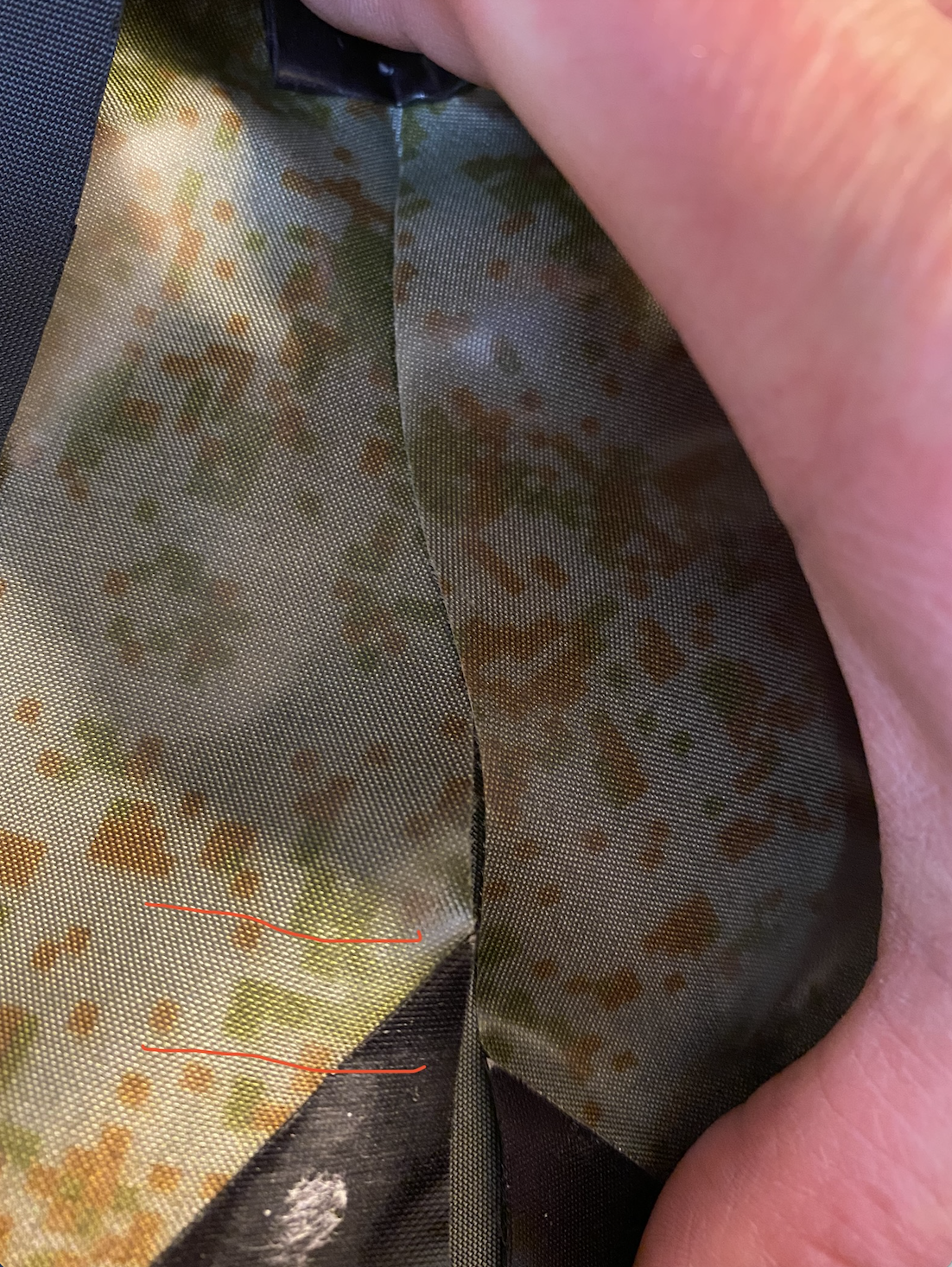

I’ve watched the videos and damn do you make it look easy on that Telkwa! I have a Skeena and I’m having a lot of trouble with the center seam in front. I did just fine up until where the nose really starts to point. I just can’t seem to get the two edges lined up without creating wrinkles between the tube fabric and reinforcing strip. I’m using the form per the pattern provided. I’m thinking about just making a smaller version with a tighter radius, but I’m not sure that will work either.

Any pointers or additional tips would be really helpful! Thanks in advance

Viewing 4 reply threads

Viewing 4 reply threads

- You must be logged in to reply to this topic.

I’m leaving this here in case someone else has a similar issue

I’m leaving this here in case someone else has a similar issue