Introduction

This page is an introduction to inflatable packraft fabrics for the general reader. It’s a good place to start if you have never worked with fabrics before.

Fabric and Coating Types

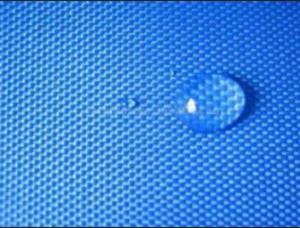

Most (if not all) decent packraft manufacturers make their boats out of nylon fabric that is coated with thermoplastic polyurethane (TPU). This combination of materials is strong, airtight, waterproof, UV resistant, stretches to absorb impacts, and retains its strength and flexibility at very low and very high temperatures.

The airtight coating on the fabric, thermoplastic polyurethane (TPU), is a variant of polyurethane (PU) that bonds to itself when heated to approximately 200 °C (~400 °F). It forms a very strong, permanent bond, eliminating the need for sewing or gluing – perfect for those of us who have no sewing experience and don’t want to breathe noxious glue fumes. The resulting weld is usually stronger than the fabric itself, so additional sewing or gluing would be redundant. (To see how I activate the heat-sealable coating to bond the seams, check out the Heat-Sealing Technique page.)

TPU can have a glossy or matte surface finish, and can be made colorless and transparent (to show the fabric color beneath) or it can be made opaque and colored.

TPU can be applied to one side of the woven fabric (single coated), or to both sides (double coated). Double coated fabrics may have different finishes on each side (e.g. glossy on one side, matte on the other).

TPU cannot be used as a “glue” to weld a coated fabric to a non-TPU surface – it only fuses to other TPU surfaces. (It will stick to other surfaces, such as uncoated fabrics, but it only forms a weak bond.)

Cheaper pool toy-type boats are often made of polyvinyl chloride (PVC, a type of vinyl), or PVC-coated fabric. (Kokopelli now makes a PVC packraft.) Compared to TPU, PVC is heavier, weaker, brittle when cold, and gives off noxious fumes when heated to high temperatures. The only advantage of PVC is that it’s cheap.

Fabric Strength & Weight

One way to classify fabric is by “denier” (D), which is a measure of the thread weight, with 1 denier equalling the weight of a single strand of silk, and higher denier numbers indicating heavier (and therefore thicker and stronger) thread. The relationship between denier number and fabric weight and strength is not linear, however, because the thread count (T) must also be taken into account. Thread count indicates the number of threads per square inch in the fabric, and a higher thread count at a given denier will be heavier and stronger. As the denier increases, thread count generally decreases, because the number of threads that can be packed into a square inch decreases as the threads become thicker. For fabrics of a given denier, you are unlikely to have options of different thread counts (indeed, T is not even listed in many fabric descriptions), so don’t worry about it too much – just be aware that a 400D fabric is not twice as strong as a 200D fabric (not even close), an 840D fabric is not twice as strong as a 420D fabric, and so on.

Not all fabrics of a given denier are created equal – thread count, polymer type, and fabric quality are also important factors. Nylon has different properties compared to polyester, for example, and even nylon itself has several variants, with some being better than others for packraft construction.

Typical name-brand packraft tubes are made of 210D fabric with a TPU coating on one side, while the floors are 840D and coated on both sides. This makes for an typical packraft weight of about 2.5 kg, or 6 pounds.

The thickness of TPU coatings is usually expressed in decimal millimetres, though it is rarely advertised in product descriptions.

An alternative indication of fabric strength is grams per square meter (GSM). The weight per unit area is equal to the denier times the thread count plus the weight of any coatings applied. Because denier, thread count, and TPU coatings all contribute to the strength of a fabric, GSM can be a better indication of strength than denier alone. GSM is not a good way to compare fabrics that are coated with TPU on both sides to fabrics that are coated on only one side, however, because in double coated fabrics, a much higher proportion of the weight is made up of the lower strength TPU.

In the USA, fabric and coating weights are often described in ounces (oz), which indicates the weight of one square yard of the fabric (1 oz per square yard = 33.9 grams per square meter). The weights of fabrics with coatings are sometimes notated something like “1/3.9 oz”, which would be a 3.9 oz fabric with a 1 oz coating. It gives you a sense of the total weight per square yard (4.9 oz, in this example), and how heavy the coating is relative to the woven fibers.

Fabric Weaves

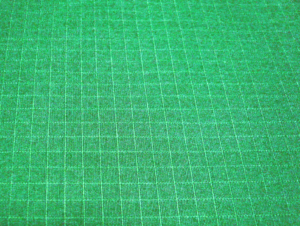

There are several types of weave you might come across when reading fabric descriptions, such as ripstop (a square or diamond pattern made by weaving thicker strands into the fabric to help stop rips from propagating – common in tents, backpacks and other lightweight outdoor gear), oxford (a tiny checkered pattern made by bundles of threads cris-crossing each other – common in fabrics heavier than about 200D), taffeta (each strand is woven separately, producing no pattern other than an extremely fine criss-cross – like silk and waterproof-breathable jackets).

Other terms you might come across: Cordura is a brand name pack cloth, and pack cloth is a generic term for tough fabrics, which generally have an oxford weave. Ballistic nylon is also a term used to describe tough, heavy nylon fabric with an oxford weave. Cordura, pack cloth, and ballistic nylon are commonly used in high-wear, high-stress applications such as luggage straps.

I also did some research into the new non-woven, ultra lightweight, high-tech polymers such as Cuben Fiber, (now re-branded as Dyneema Composite Fabric). Unfortunately, they are not very puncture-resistant, despite being very strong under tension, so while they are great for tents, sails, and lighter-than-air craft, they aren’t really suitable for packrafts. They are also extremely expensive.

How Fabric is Measured and Sold

Fabric is generally sold by length, cut from a roll (measured by the yard or the metre, depending on the country). There is no standard width for fabric rolls, but all of the fabrics you are likely to find will probably be approximately 145 cm (57″) wide, give or take a few cm/inches. If purchasing online, look for the width in the product description. The usable width is often slightly less (usually ~3-5 cm or 1-2″) than the advertised width because of the “selvage” (rough, unfinished edges), so take that into account if you are laying out your own patterns. When comparing prices between suppliers from the US and elsewhere, don’t forget to convert yards to metres or vice versa, depending on what units you’re working with – the difference is almost 10% (1 metre = 1.09361 yards).

Shipping costs can be quite high relative to the cost of the fabric, so don’t just look at the advertised price – get a quote including shipping before deciding where to buy. You may also have to pay taxes or import duties, depending on where you live and where you are ordering from. I have written more about this here.

Calculating the amount of fabric needed for a project is more complicated than simply calculating the area of the fabric used in the project itself, because some amount of fabric will be wasted as you cut out the irregular shapes that will join up, and if the fabric is coated on one side only, that means you can only lay out the shapes each with a particular side facing up (the shapes might fit together better if you flip one over, but unless the parts are symmetrical then some might end up with the coating on the wrong side). Check out the How Much Fabric Do I Need? page for more on this topic.

Choosing Your Fabric

When choosing a fabric for a packraft (or any other piece of gear), it’s important to think about what you’ll use it for and also how you tend to treat your gear. Are you a whitewater paddler who wants to scrape down shallow rivers full of sharp rocks and sticks, or are you an ultralight hiker who is careful with your gear and most concerned about weight? The trade-off between strength and weight, combined with your willingness to make field repairs, will determine what fabric or fabrics will work best for you.

For example, I’m pretty careful with my gear, but I also wanted to be able to run some mild whitewater in my first packraft. I purchased many samples and then settled on a very lightweight TPU-coated ripstop for my first boat. For my purposes, it was a good compromise between strength and weight, and the full-size packraft I made from it weighs just 813 grams, or 1.79 pounds with a double layer of fabric on the floor. It performs very well on flat water, but is not durable in shallow moving water with sharp sticks (as I soon found out). It’s easy to repair though, and I’m comfortable making field repairs, so this was not a problem for me. Your needs may be different.

Sourcing Fabric Elsewhere

The fabrics in the DIY Packraft shop are custom made to my specifications, and all of my instructions and recommendations are based on the assumption that you are using these fabrics. You are more than welcome to purchase fabric elsewhere – just be aware that the only reason I started the DIY Packraft shop in the first place was that there weren’t any fabrics like this available online. Also be aware that the recommended tools and techniques may not work well with other fabrics – always test a sample before purchasing a large quantity.

TPU Coating In or Out?

You may wonder whether it’s better to put the TPU-coated side of the fabric on the inside or outside of a packraft or other piece of inflatable gear. I have tried both, and either way works, but I prefer the TPU-out configuration for larger projects like packrafts, and TPU-in for smaller things like seats. TPU-out has the advantage of not soaking up any water weight and having a slipperier, abrasion resistant surface facing out. TPU-in allows for internal structural elements to be attached (such as seat baffles) and makes ironing easier because you can touch the fabric directly with your iron.

83 Comments

Liza · February 21, 2024 at 12:06 pm

Hi,

I am looking for material recommendations for an inflatable. A flexible pouch that can inflate and deflate when i put in water. Ability to withstand pressures and hot conditions (>75C).

Lillia Slemmons · January 8, 2024 at 12:47 pm

My husband needs this fabric for a different project and we’re having a hard time find the TPU online , any sources to buy the fabric in bulk would be greatly appreciated, thank you!!

Matt (Admin) · January 8, 2024 at 1:48 pm

Suggestions are here:

https://www.diypackraft.com/faq/do-you-sell-fabric-by-length/

Michael Dexter · December 26, 2023 at 5:39 pm

So I have an application that I want to be able to put water on the inside of a vessel and then pressurize it to a degree nothing crazy but probably a few PSI. I am assuming that if a pack craft can keep water from going into a pressurized air bladder, then it would also keep water from escaping a pressurized bladder. Is that correct or is the TPU coating water permeable at certain pressures? Thanks for your help!

Matt (Admin) · December 27, 2023 at 10:05 am

Yep, that should work fine. I would recommend orienting the fabric so the TPU is on the inside of the bladder, facing the water.

JimmyJames · November 23, 2023 at 2:42 am

What fabric would you recommend for over-ear or on-ear inflatable for stuffing inside or behind speakers inside of snowmobile helmet? Must be able to withstand harsh climates. The idea is to create a seal around the ear to get a noise cancelling affect within the helmet. Any/all advice is welcomed and will be greatly appreciated! Thanks in Advance. -JimmyJames

Matt (Admin) · November 23, 2023 at 8:56 am

I’d probably buy some replacement ear cups/ear pads for an aviation headset or helmet.

Devon · April 5, 2023 at 5:12 am

Was wondering if you had any new insight on how to RF Seal coated dyneema without the use of Tape? I am researching dyneema to use as an alternative in some of our rafts,

Matt (Admin) · April 5, 2023 at 8:42 am

I don’t, but maybe their sales people can connect you with someone who does.

ey63210 · November 9, 2022 at 2:44 am

Sorry to drag this up.

I tried to find the answer online but No success.

Why doesn’t anyone use kevlar to make packrafts? Except for kokopellis “blend” (don’t understand how this blend works anyhow since I understand these materials have a very different melting point)

Is it as simple as kevlar having a way too high melting point which hinders a good fusing of tubes and floor etc?

Matt (Admin) · November 9, 2022 at 9:26 am

I tested some TPU-coated aramid (Kevlar) fabrics, but I didn’t find them to be worth their exorbitant prices (about five times the cost of the fabrics I currently use, and the TPU coating doesn’t bond as well to the aramid, so even though the fabric didn’t rip easily, it failed in a different way that would be more difficult to repair). A “blend” fabric would have some percentage of aramid strands woven in with the other yarn, kind of like a ripstop fabric. Last I checked, Kokopelli only uses their Kevlar blend on the floor fabric, which is the least important fabric – see my page titled “How to Choose a Packraft (not just DIY)” for more on this – and they don’t say what percentage of the fabric is Kevlar, so in my opinion it’s more of a marketing gimmick than a real advantage.

Barb Gauthier · October 22, 2022 at 1:36 pm

Hi! I am looking for a urethane-coated nylon fabric to replace the decking on snowshoes. Do you have a fabric that would work for this application? If not, any idea where I might find some? Thanks a lot!

Matt (Admin) · October 24, 2022 at 10:34 am

The 450 GSM fabric offcuts and seconds in the shop would work – there’s none in stock now, but check back from time to time. If you’re looking for something right away, I can’t help you.

Max · January 5, 2022 at 11:50 am

Hi Matt, thanks for your great website and products. I was wondering if you could tell me the difference in strength, weight and pros/cons of using single-sided TPU vs. double-sided for the tubes of packrafts. Thanks.

Matt (Admin) · January 12, 2022 at 9:45 am

The short answer is that for a given weight, double-sided fabric is weaker than single-sided fabric (holding everything else constant). A full analysis is beyond what I can do here, but like any engineering problem it comes down to making tradeoffs between many factors, such as weight, strength, durability, cost, workability, design complexity, product availability, and so on, and you have to weigh each factor based on the design goals of a particular project.

pete popham · November 17, 2021 at 4:41 am

how would i repair a rip/ tear or hole in fabric?

Matt (Admin) · November 17, 2021 at 8:32 am

That would depend on the fabric and the size of the hole. If you’re talking about a DIY Packraft, you can simply heat seal a scrap of the same fabric over the hole.

Christophe Simonsen · May 20, 2021 at 2:26 am

What would you suggest for a fabric that is lightweight (about 5 oz/yard or < 0,005" thick), flexible, and 100% light tight? I would like to make bellows for cameras. Thanks for your sugestions !

REPLY

Jordan Head · April 6, 2021 at 9:09 pm

What would you suggest for a fabric that is lightweight, flexible, and airtight? Thinking about trying to make my own raft that I can pack with me cause i’m a fisherman, ideally something that I could iron seal. Any suggestions would be helpful! Thanks

Matt (Admin) · April 7, 2021 at 8:49 am

https://www.diypackraft.com/shop/

Cliff · February 27, 2021 at 12:03 am

Hey Matt, great website! Thanks for all your hard work and effort at helping people make their own packrafts! I love packrafting and have been doing it for a few years. I’m also a hobbyist inventor, product-designer, and self-professed science/technology nerd.

I’ve read much of your website, including the info about fabrics and “can I make a packraft from ‘x’ fabric?” I wondered if you have experience (or know of anyone else with experience) using RipstopbytheRoll’s “3.9 oz Venom UHMWPE TPU Coated” fabric to make a packraft (see https://ripstopbytheroll.com/products/3-9-oz-venom-uhmwpe-tpu-coated)? It’s a super-high performance (and expensive) fabric that seems well-suited for packrafts. It is essentially a woven version of dyneema with a TPU coating on both sides. Since it’s woven (and not a laminate like composite dyneema), it should resist punctures much better. I just ordered a sample to test and evaluate, but if you watch the test video on the website, you’ll see how incredibly tough it is compared to other materials.

I’m contemplating ordering your ultralight kit, then substituting the Venom fabric for the fabric your kit comes with. Would be grateful if you have any insight or feedback to share. Thank you.

Matt (Admin) · February 27, 2021 at 12:00 pm

I only know of one other person who was going to try this, and he didn’t get back to me with his results, so I’m assuming he gave up and/or it wasn’t a great success, but I could be wrong. I think the fabric has great potential, but the main problem (aside from price) is that UHMWPE breaks down at high temperatures, so heat welding may drastically reduce the seam strength. If you try it out, please share the results!

Aaron · February 27, 2021 at 1:57 pm

I’ve also ordered samples of the TPU coated Venom fabric. According to this video from Dyneema (https://www.youtube.com/watch?v=g_0f8DM9Ab4) the TPU film that is bonded to their fabrics has a melting temperature of 135 degrees C, which is just below the temperature that UHMWPE begins breaking down. Besides being enormously expensive, it would probably be difficult to make a full packraft out of this material since it is coated on both sides. Wouldn’t that make joining the tubes to the floor incredibly messy? It could be interesting to swap this in as the floor fabric in a Skeena or Telkwa kit; you could shave off weight and the packed size would probably be smaller. However, welding together TPU layers with such dissimilar melting points might be impossible. I think the only way to get it to work would be to pre-heat the high melting point TPU by first giving it a few passes with a hot air gun, then quickly pressing the Venom on top. I still have a hard time imagining that the weld would be as strong as it is with two layers of TPU with matched melting points, but I might be wrong. I’ll give it a shot when the samples arrive from Ripstop by the Roll.

Dyneema says that they’ll be introducing more TPU-coated UHMWPE products in the next couple of years. Maybe that’ll include a fabric coated on only one side, which could be used for the tubes and seam strips for a packraft with a Venom floor.

Aaron · March 3, 2021 at 7:17 pm

The TPU coating on this fabric is so thin that it’s hardly noticeable, it’s not thick enough for effective heat sealing. I tried a range of temperatures from 130-150C (I used a hotplate and confirmed the temperature with an infrared thermometer), and the best I could could get was a slightly tacky bond that was easily peeled apart. I had fun playing around with the fabric, the tear resistance and tensile strength are outrageous, noticeably greater than Matt’s 210d nylon. The puncture resistance seems slightly worse though.

Matt (Admin) · March 4, 2021 at 10:22 am

Interesting – thanks for telling us!

Bruce · January 26, 2021 at 6:37 am

Are all the fabrics bonding temperature at about 200C?

Brilliant video and blog site, informative and clear keep up the great work

Matt (Admin) · January 26, 2021 at 1:33 pm

Thanks!

Approximately, yes.

Tony S · June 18, 2020 at 12:35 pm

Thanks for the write up. This is very useful. I’m specifically interested in Kokopelli’s unique blending of 210D TPU blended with DuPont Kevlar Aramid Nylon Blend. How much stronger is this specific fabric compared to others? And is there anyway DIY folks can get their hands on such specialty fabric?

Matt (Admin) · June 18, 2020 at 6:40 pm

Unfortunately companies don’t publish data about their proprietary fabrics, so the only way to know would be to buy a packraft and destroy it. Nearly all technical fabrics are custom made for the business that uses them in their products (including the DIY Packraft fabrics), so I doubt you will find something like Kokopelli’s blended fabric for sale anywhere. They don’t say what percentage of the threads are aramid, and last time I checked they only used that fabric in the floors so I consider it more of a marketing gimmick than a notable feature. The floor is the least important part of the packraft because the floor doesn’t need to be airtight – the packraft floats just fine when there’s a hole in the floor (self-bailing packrafts have holes in the floors for water to drain out). The tube fabric is what matters.

clive taylor · May 31, 2020 at 4:10 pm

I wish I would have seen this video a week ago,I have been searching the web and asking on camping forums asking about material to make a fly /rain cover to no avail for my tent ,now I can see the strength of the 250d material thank you for an informative video ..brilliant

Francesco Bertelli · May 3, 2020 at 6:31 am

Nice blog! Can I ask you where do you find tpu samples? Are there suppliers in USA that you can recommend?

Matt (Admin) · May 3, 2020 at 9:33 am

Sorry, I don’t know.