Introduction

This page is an introduction to inflatable packraft fabrics for the general reader. It’s a good place to start if you have never worked with fabrics before.

Fabric and Coating Types

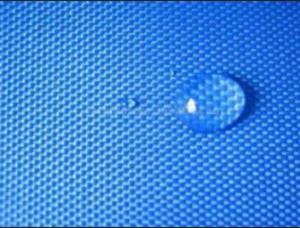

Most (if not all) decent packraft manufacturers make their boats out of nylon fabric that is coated with thermoplastic polyurethane (TPU). This combination of materials is strong, airtight, waterproof, UV resistant, stretches to absorb impacts, and retains its strength and flexibility at very low and very high temperatures.

The airtight coating on the fabric, thermoplastic polyurethane (TPU), is a variant of polyurethane (PU) that bonds to itself when heated to approximately 200 °C (~400 °F). It forms a very strong, permanent bond, eliminating the need for sewing or gluing – perfect for those of us who have no sewing experience and don’t want to breathe noxious glue fumes. The resulting weld is usually stronger than the fabric itself, so additional sewing or gluing would be redundant. (To see how I activate the heat-sealable coating to bond the seams, check out the Heat-Sealing Technique page.)

TPU can have a glossy or matte surface finish, and can be made colorless and transparent (to show the fabric color beneath) or it can be made opaque and colored.

TPU can be applied to one side of the woven fabric (single coated), or to both sides (double coated). Double coated fabrics may have different finishes on each side (e.g. glossy on one side, matte on the other).

TPU cannot be used as a “glue” to weld a coated fabric to a non-TPU surface – it only fuses to other TPU surfaces. (It will stick to other surfaces, such as uncoated fabrics, but it only forms a weak bond.)

Cheaper pool toy-type boats are often made of polyvinyl chloride (PVC, a type of vinyl), or PVC-coated fabric. (Kokopelli now makes a PVC packraft.) Compared to TPU, PVC is heavier, weaker, brittle when cold, and gives off noxious fumes when heated to high temperatures. The only advantage of PVC is that it’s cheap.

Fabric Strength & Weight

One way to classify fabric is by “denier” (D), which is a measure of the thread weight, with 1 denier equalling the weight of a single strand of silk, and higher denier numbers indicating heavier (and therefore thicker and stronger) thread. The relationship between denier number and fabric weight and strength is not linear, however, because the thread count (T) must also be taken into account. Thread count indicates the number of threads per square inch in the fabric, and a higher thread count at a given denier will be heavier and stronger. As the denier increases, thread count generally decreases, because the number of threads that can be packed into a square inch decreases as the threads become thicker. For fabrics of a given denier, you are unlikely to have options of different thread counts (indeed, T is not even listed in many fabric descriptions), so don’t worry about it too much – just be aware that a 400D fabric is not twice as strong as a 200D fabric (not even close), an 840D fabric is not twice as strong as a 420D fabric, and so on.

Not all fabrics of a given denier are created equal – thread count, polymer type, and fabric quality are also important factors. Nylon has different properties compared to polyester, for example, and even nylon itself has several variants, with some being better than others for packraft construction.

Typical name-brand packraft tubes are made of 210D fabric with a TPU coating on one side, while the floors are 840D and coated on both sides. This makes for an typical packraft weight of about 2.5 kg, or 6 pounds.

The thickness of TPU coatings is usually expressed in decimal millimetres, though it is rarely advertised in product descriptions.

An alternative indication of fabric strength is grams per square meter (GSM). The weight per unit area is equal to the denier times the thread count plus the weight of any coatings applied. Because denier, thread count, and TPU coatings all contribute to the strength of a fabric, GSM can be a better indication of strength than denier alone. GSM is not a good way to compare fabrics that are coated with TPU on both sides to fabrics that are coated on only one side, however, because in double coated fabrics, a much higher proportion of the weight is made up of the lower strength TPU.

In the USA, fabric and coating weights are often described in ounces (oz), which indicates the weight of one square yard of the fabric (1 oz per square yard = 33.9 grams per square meter). The weights of fabrics with coatings are sometimes notated something like “1/3.9 oz”, which would be a 3.9 oz fabric with a 1 oz coating. It gives you a sense of the total weight per square yard (4.9 oz, in this example), and how heavy the coating is relative to the woven fibers.

Fabric Weaves

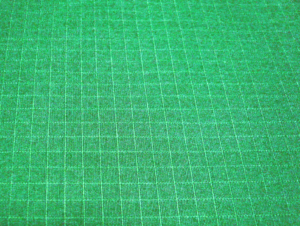

There are several types of weave you might come across when reading fabric descriptions, such as ripstop (a square or diamond pattern made by weaving thicker strands into the fabric to help stop rips from propagating – common in tents, backpacks and other lightweight outdoor gear), oxford (a tiny checkered pattern made by bundles of threads cris-crossing each other – common in fabrics heavier than about 200D), taffeta (each strand is woven separately, producing no pattern other than an extremely fine criss-cross – like silk and waterproof-breathable jackets).

Other terms you might come across: Cordura is a brand name pack cloth, and pack cloth is a generic term for tough fabrics, which generally have an oxford weave. Ballistic nylon is also a term used to describe tough, heavy nylon fabric with an oxford weave. Cordura, pack cloth, and ballistic nylon are commonly used in high-wear, high-stress applications such as luggage straps.

I also did some research into the new non-woven, ultra lightweight, high-tech polymers such as Cuben Fiber, (now re-branded as Dyneema Composite Fabric). Unfortunately, they are not very puncture-resistant, despite being very strong under tension, so while they are great for tents, sails, and lighter-than-air craft, they aren’t really suitable for packrafts. They are also extremely expensive.

How Fabric is Measured and Sold

Fabric is generally sold by length, cut from a roll (measured by the yard or the metre, depending on the country). There is no standard width for fabric rolls, but all of the fabrics you are likely to find will probably be approximately 145 cm (57″) wide, give or take a few cm/inches. If purchasing online, look for the width in the product description. The usable width is often slightly less (usually ~3-5 cm or 1-2″) than the advertised width because of the “selvage” (rough, unfinished edges), so take that into account if you are laying out your own patterns. When comparing prices between suppliers from the US and elsewhere, don’t forget to convert yards to metres or vice versa, depending on what units you’re working with – the difference is almost 10% (1 metre = 1.09361 yards).

Shipping costs can be quite high relative to the cost of the fabric, so don’t just look at the advertised price – get a quote including shipping before deciding where to buy. You may also have to pay taxes or import duties, depending on where you live and where you are ordering from. I have written more about this here.

Calculating the amount of fabric needed for a project is more complicated than simply calculating the area of the fabric used in the project itself, because some amount of fabric will be wasted as you cut out the irregular shapes that will join up, and if the fabric is coated on one side only, that means you can only lay out the shapes each with a particular side facing up (the shapes might fit together better if you flip one over, but unless the parts are symmetrical then some might end up with the coating on the wrong side). Check out the How Much Fabric Do I Need? page for more on this topic.

Choosing Your Fabric

When choosing a fabric for a packraft (or any other piece of gear), it’s important to think about what you’ll use it for and also how you tend to treat your gear. Are you a whitewater paddler who wants to scrape down shallow rivers full of sharp rocks and sticks, or are you an ultralight hiker who is careful with your gear and most concerned about weight? The trade-off between strength and weight, combined with your willingness to make field repairs, will determine what fabric or fabrics will work best for you.

For example, I’m pretty careful with my gear, but I also wanted to be able to run some mild whitewater in my first packraft. I purchased many samples and then settled on a very lightweight TPU-coated ripstop for my first boat. For my purposes, it was a good compromise between strength and weight, and the full-size packraft I made from it weighs just 813 grams, or 1.79 pounds with a double layer of fabric on the floor. It performs very well on flat water, but is not durable in shallow moving water with sharp sticks (as I soon found out). It’s easy to repair though, and I’m comfortable making field repairs, so this was not a problem for me. Your needs may be different.

Sourcing Fabric Elsewhere

The fabrics in the DIY Packraft shop are custom made to my specifications, and all of my instructions and recommendations are based on the assumption that you are using these fabrics. You are more than welcome to purchase fabric elsewhere – just be aware that the only reason I started the DIY Packraft shop in the first place was that there weren’t any fabrics like this available online. Also be aware that the recommended tools and techniques may not work well with other fabrics – always test a sample before purchasing a large quantity.

TPU Coating In or Out?

You may wonder whether it’s better to put the TPU-coated side of the fabric on the inside or outside of a packraft or other piece of inflatable gear. I have tried both, and either way works, but I prefer the TPU-out configuration for larger projects like packrafts, and TPU-in for smaller things like seats. TPU-out has the advantage of not soaking up any water weight and having a slipperier, abrasion resistant surface facing out. TPU-in allows for internal structural elements to be attached (such as seat baffles) and makes ironing easier because you can touch the fabric directly with your iron.

83 Comments

e.ian.howick · June 13, 2019 at 6:57 pm

Do you still/will you have 560 GSM fabric available again? Would be buying 7 m of it if you have in stock to skin a largish double folding kayak.

Matt (Admin) · June 14, 2019 at 8:00 am

I’m currently looking for a replacement for this fabric… stay tuned!

Daniel Watson · June 11, 2019 at 8:39 pm

I am interested in getting a packrafting but I was wondering if you had an option with a Kevlar floor material.

Matt (Admin) · June 12, 2019 at 9:03 am

I do not currently have any Kevlar fabrics.

John Baldwin · March 18, 2019 at 2:37 pm

I am wanting to make waterproof bags to tow behind a backcountry skier on snow as a super lightweight alternative to a toboggan. I have heard of people dragging their packrafts over snow. Any sense of how durable the fabrics would be or which fabric would be most suitable. Could I use the 115 GSM fabric? Would this stand up to 20 days of dragging on snow? Obviously heavier will last longer but lighter weight is key since the bag will have to be carried as well.

Matt (Admin) · March 18, 2019 at 3:05 pm

Hi John, you might be able to make an inflatable pulk, but I don’t know about just using a bag… I think it would create a lot of drag if you had stuff inside the bag poking down into the snow, especially in powder. A pulk or packraft or toboggan spreads the load evenly over a large area and it’s easy to pull because you don’t have to plow a furrow through the snow. (If you’ve ever tried to slide down a snow slope on a plastic bag you’ll know what I mean – you just sink in and can’t get going unless the snow is really consolidated.) An inflatable bottom layer (or at least an inflatable camping mattress inside the bag under your gear) might help, but unlike a pulk it wouldn’t have any directional stability, which could be a problem on steeper descents in icy conditions. I’ve used the lightweight fabrics on snow and they held up fine (I posted a video of riding down a ski hill on one of my ultralight packrafts), but if you expect to cross any dirty snow with rocks or tree branches I’d choose something heavier. A fabric sample pack might help you decide. Cheers!

alex · June 30, 2018 at 2:04 am

Hi, I would like to make a new outer skin for a pack raft that I brought from fly weight designs. The pack raft consists of an inner tube with an outer skin that has an elastic band running around it’s edge. The inner tube simply sits inside the outer skin by virtue of the elastic band holding it in place. I need the strongest material possible and am not so much worried about weight. Do you know which kind of material would be suitable? Where would I get it from? I am in England at the moment but I usually live in Australia.

Matt (Admin) · June 30, 2018 at 10:03 am

For an application like that I might use a heavy nylon Oxford fabric because it’s relatively cheap and durable. You’ll have to search for a local source.

alex · July 1, 2018 at 12:25 am

Thank you. Will have a look.

Emilio · May 5, 2018 at 11:28 pm

Necesito nylon TPU 210 para fabricación de inflable

Keith Kreycik · April 7, 2018 at 5:49 pm

Hi, how do I specify the color combination for a multicolor DIY packraft? My spouse liked the looks of the red/yellow combo in the pictures (predominately red with four yellow tube sections)

Matt (Admin) · April 8, 2018 at 1:40 pm

If you scroll down on the V3 kit product page, instructions are posted there. Cheers!

Bill · March 29, 2018 at 9:05 pm

On the V3 does the floor material wrap up around the tubes to give more protection for bony water, that seems like it would be beneficial? If it’s not laid out that way, what would be the best way to achieve covering additional side tube with floor material? I’ve been reading the threads trying to decide gleam information pertinent to durability. I am planning a trip in the back country with up to class III white water and want to feel comfortable that barring human error these rafts are up to the task. Have many people been running class III white water and how have your boats been doing?

Mark · March 30, 2018 at 11:57 am

It would be very easy to add extra protection on the tubes after the raft is built. Currently on my V3, the floor doesn’t wrap up very far (and I wouldn’t actually want it to… I’m using the 1000D floor and while it’s hella sturdy, it also doesn’t fold up very tight). I think the best solution would be to order an extra yard of 210D material. Then you could very easily make a wide strip that you could seal to the floor and to the tubes for extra protection against sharp rocks and branch pokes. This could be done after the raft is completed.

lars · March 5, 2018 at 9:02 am

Hi Matt, I noticed that the new kokopelli rogue has a kevlar floor material. Is this marketing hype or is there worthwhile value? Is this something we might expect to see here in the future?

Matt (Admin) · March 5, 2018 at 5:10 pm

Hi Lars, it seems like more of a gimmick than a real improvement to me. The way I see it, it makes more sense to reinforce the weak parts of the packraft, not make the strongest parts even stronger. You could riddle a packraft’s floor with holes and it wouldn’t perform much differently because it’s the tubes that hold air and give the boat its shape, not the floor. If you look at a picture of the bottom of the Rogue, the floor material doesn’t wrap up around the tubes at all, so it really offers no protection in that regard. It might protect the inflatable seat, but if you’re hitting something hard enough to rip a standard floor it will almost certainly rip the tubes as well. This is just my opinion, of course 🙂

Lars · March 6, 2018 at 4:19 pm

Thanks Matt. Those are really good points.

Shane · August 22, 2017 at 5:41 pm

Very informative. Thanks! I am looking for a lightweight fabric to go inside a float tube shell. In the army we had yellow water flotation wings. Do you know what kind of material that is? What kind of lightweight fabric would you suggest? Also, are welded seams better than glued? Thank you.

Matt (Admin) · August 23, 2017 at 7:43 pm

Most inflatable life jackets I have seen are made from TPU coated fabric, similar to the 210D fabric in the DIY Packraft shop, and most inflatables are welded. 40D fabric could work for your float shell if you want it to be lighter and more packable, but it’s not as resilient. Cheers!

Jayce · June 23, 2017 at 2:02 pm

I am looking for a fabric that would be good for class 4 rapids with a inflatable floor kinda like a alpaca packraft

Matt (Admin) · June 26, 2017 at 8:46 am

Which model of Alpacka are you referring to? They use several different types of fabric in their various packrafts.

Jayce · June 26, 2017 at 2:01 pm

http://www.alpackaraft.com/product/alpackalypse-2/

Matt (Admin) · June 26, 2017 at 4:28 pm

Please check back in a couple of weeks and I will have some new fabrics in stock that might suit your needs. Thanks!

Jayce · June 26, 2017 at 7:14 pm

will do

eric akse · April 24, 2017 at 7:20 am

Great site and thank you for the tons of information! I earlier sent you an email regarding the floor but my questions was answered here on this page already.

I’m also wondering where we are with the spray skirt as I would like to add that to my purchase. I will look around some more and see if that has already been answered somewhere!

Jonathan · March 12, 2017 at 10:44 pm

Excellent website, very inspiring!

Why do you recommend an 800D floor for a dedicated whitewater raft when your tests are showing that double 210D is stronger?

Also, do you happen to know why Alpacka stiches and tapes their whitewater rafts instead of sealing them, like you?

Do you think that your rafts with double 210D floors would be theoretically solid on Class 4? I just want to get a sense of how much these rafts may be able to handle.

Looking forward to picking up a kit when your new fabric arrives!

Matt (Admin) · March 13, 2017 at 9:47 am

Thanks, Jonathan – I’m glad you’re finding the site useful! The pages are constantly evolving and I probably wrote that before testing a double-layer floor. I’ve written so much it’s hard to remember what I need to go back and change when I learn something new – if you can point me to where I said that I’ll update it.

Alpacka’s founder came from a sewing background and they’ve always made their packrafts that way – it works for them, so why change?

No packraft will ever be as solid as a kayak – even the toughest $2000 packrafts at four times the weight of a DIY Packraft can’t compete with a kayak for durability. In moving water there are too many factors to consider (paddling skill, water level, wood, care taken during construction, weight of paddler and gear, risk-taking, bad luck, etc.) to answer that question with a “yes”. The best way to get a sense of the strength of the fabric is to purchase a fabric sample pack and test it for yourself.

Thanks!

Jonathan · March 12, 2017 at 10:42 pm

Excellent website, very inspiring!

Why do you recommend an 800D floor for a dedicated whitewater raft when your tests are showing that double 210D is stronger?

Also, do you happen to know why Alpacka stiches and tapes their whitewater rafts instead of sealing them, like you?

Do you think that your rafts with double 210D floors would be theoretically solid on Class 4? I just want to get a sense of how much these rafts may be able to handle.

Looking forward to picking up a kit when your new fabric arrives!

Quincy · December 28, 2016 at 12:56 pm

Thank you for all this great information.

I know that many of the best commercial pack rafts that are capable of doing white water have floors that are 800d nylon floors. Have you been able to find any fabric this heavy to use with your plans?

I see you recommend a double floor using two layers of 210d fabric, do you bond all of the two layers together or just around the edges? How does this compare to 800d fabric? Thank you.

Matt (Admin) · January 1, 2017 at 6:49 pm

Hi Quincy,

The double-layer 210D floor is comparable in strength to 800D. I bond the entire floor surface together, but I have been thinking of ways to create an inflatable floor, so that might be something I tackle in 2017. I will also be adding new fabrics to the Shop 🙂

Cheers!

Thor · January 14, 2017 at 2:48 pm

Hi Matt,

I’m super keen to make a packraft after spending hours reading through info on your website. I share Quincy’s concern about the floor especially since I live in Australia and our rivers are very rocky and if the water levels are low (most of the summer) there can be a lot of scraping over rocks. I’m willing to give the 2 layers of 210D a try, but wondering if you might be adding new floor fabric to the options any time soon, in which case I would be better to hold off for a bit. Thanks, and thanks for doing such a great job.

Matt (Admin) · January 15, 2017 at 5:39 pm

Hi Thor, I am working with the factories to develop new fabrics, but I have learned not to estimate when new products will be available because these things always take much longer than I anticipate!

Rather than building a heavier, bulkier boat out of stronger fabric, I recommend building a lighter boat and accepting the fact that you will probably have to patch it occasionally (for more on this, read my Punctures, Leaks & Repairs page). Aside from avoiding sharp objects, the best way to prevent tears in the fabric is to use an inflatable seat, padding under your heels, and store hard gear on the deck instead of on the floor. This allows the fabric to bounce, stretch, fold, and flow around obstacles instead of being pinched between a rock and a hard place.

Cheers!

Quincy · January 22, 2017 at 11:21 am

I ha e also been thinking more about this. I think another way to strengthen the floor would be if you cut one of the floor pieces rotated 45degrees so that the weave between the two layers don’t line up. The fabric rips easier along the weave so if the two different layers have two different weave directions any hole will be harder to tear. Unfortunately this will take more fabric as there wasn’t a way to fit two floor patterns in such a configuration on the 2 yards that I had…

Matt (Admin) · January 23, 2017 at 10:54 am

Hi Quincy, I think you’re right, but as long as the threads are not exactly parallel it should have a similar effect, and they are unlikely to be exactly parallel. Cheers!

Harry · August 15, 2016 at 11:32 am

I would like to make inflatable pontoons for a small raft suitable for leisurely bobbing down a river. I am thinking of sewing the pontoons out of a tough fabric and inserting inflatable bladders constructed out of TPU+PU fabric with the PU side facing out. Do you see any immediate flaws with this plan? One thing that comes to mind is that the PU side of the fabric will be rubbing against the pontoon shell which might test it’s resistance to abrasion.

Matt (Admin) · August 15, 2016 at 1:06 pm

Hi Harry,

I think for leisurely bobbing down a river a double layer of fabric might be overkill unless you’re expecting to encounter very sharp rocks and sticks, but I don’t see any obvious flaws with that configuration. Bakraft packrafts are made in a similar way. Movement between the inner and outer layers would be minimal, so I doubt internal abrasion would be an issue. Let me know how it goes!

~Matt

Craig · June 22, 2016 at 5:01 am

Matt,

Regarding the inflation bag, is there an additional fitting needed to attach the inflation bag to the inflation valve?

Would having the TPU coating on the outside be better for in the field puncture repairs and also for added tie down attachments?

Thanks

Matt (Admin) · June 22, 2016 at 11:28 am

I recommend gluing a short length of rubber or plastic tubing into the inflation bag that will pressure-fit snugly into the valve – I will post a more detailed explanation.

I would recommend having the TPU coating on the outside of the tubes for the fabric that you were considering – mainly because it has no coating on the other side so it would soak up water if the TPU was on the inside, but also for attaching tie-downs and making field repairs.

Cheers

Craig · June 21, 2016 at 4:38 am

How much material do you recommend for the regular size packraft?

Matt (Admin) · June 21, 2016 at 10:04 am

For the regular size packraft, each side will require just over 2.5 m (2.75 yds), and 6 m (~6.5 yds) will be enough for the tubes and the floor, even allowing for a double layer on the floor (regardless of whether you make it TPU coating in or out). You may want an extra metre (or yard) of fabric if you plan to make a seat or any other accessories.

Craig · June 19, 2016 at 1:15 pm

Hello,

I am really interested in making my own packraft. I would like to try bicycle pack rafting so I think I would want a stronger material than you used for your white prototype as I would be lashing my bicycle to the raft.

Would the material from Seattle Fabrics listed below work? Also, when do you think you may be selling fabrics?

Thanks, Craig

Heat Sealable Oxford

200 Denier (aprox. 6.5 oz./sq. yard). Lighter and more flexible than the 430 D. Packcloth, 200 D Heat sealable Oxford has a special coating that makes it possible to be heat-sealed, coated side to coated side, using a household iron.

Matt (Admin) · June 19, 2016 at 1:43 pm

Hi Craig,

Yep, I’ve played around with samples of that fabric and it should work and be tough enough for bike rafting. I will be offering a similar fabric, probably in August, but mine will have a TPU coating on one side and PU on the other, instead of just TPU on one side.

Cheers,

Matt

Korn · May 15, 2016 at 12:50 am

Hi, the German online store “Extremtextil” sells TPU coated nylon directly to customers and will ship it across the world if you want to.

Matt (Admin) · May 16, 2016 at 9:49 am

Thanks for the tip! I will check them out.

Adrian · June 1, 2016 at 1:49 pm

Did you order from them? This looks like the material you describe for the tubes:

http://www.extremtextil.de/catalog/Nylon-210den-TPU-coated-both-sides-420g-sqm-heat-sealable::1701.html

Matt (Admin) · June 1, 2016 at 2:39 pm

Hi, I have not ordered from them, myself. I can’t get that link to work, but it looks like that particular fabric has heat sealable coatings on both sides, so it wouldn’t be suitable for constructing a packraft using my methods (the iron would stick to the fabric). It’s fine to have a TPU coating on one side and a PU coating on the other, but not TPU on both sides.

Cheers!

Adrian · June 1, 2016 at 2:43 pm

Oh, yes, I realized that after I posted (and emailed you 🙂 ). They have single side TPU coating also:

http://www.extremtextil.de/catalog/Nylon-210den-TPU-coated-one-side-275g-sqm-heat-sealable::1700.html

Matt (Admin) · June 1, 2016 at 4:10 pm

Others have tried this material with mixed results… see the topic in the forum about alternative sources for materials. If you can get it to work it will have a similar strength and weight to the big packraft manufacturer’s tube material.

Pat · May 11, 2016 at 5:00 pm

Hello there, nice report very interesting ,I am in the position as you ; I want a packraft but don’t like the idea of to much $$ .

as i am looking for a more whitewater (III-IV)and rocky river

did you a have a suggestion for the fabric ..just to give me an idea of the mat’l that i have to buy

Your site is very nice and helpful

thank you

Dan Slick · May 29, 2018 at 11:43 am

I’m interested in making a few inflatable ducks of my own design, 5-6 foot tall (and long?) for use as art and as blues for a swim race. Also would like to make one I could fill with helium to float above the water. So for me light weight is good, but a question arises:

I assume the tpu side is the heat bonding side. Yet, when I make it, I glue it together one way, then turn it inside out. That would place the tpu side on the outside when finished, correct? But something tells me that’s not the preferable side for the outside of the object.

Is my understanding correct? If so, do you have a suggestion?

Matt (Admin) · June 4, 2018 at 11:20 am

Hi Dan – you can orient the TPU on either the inside or the outside of the inflatable, so no worries there. Cheers