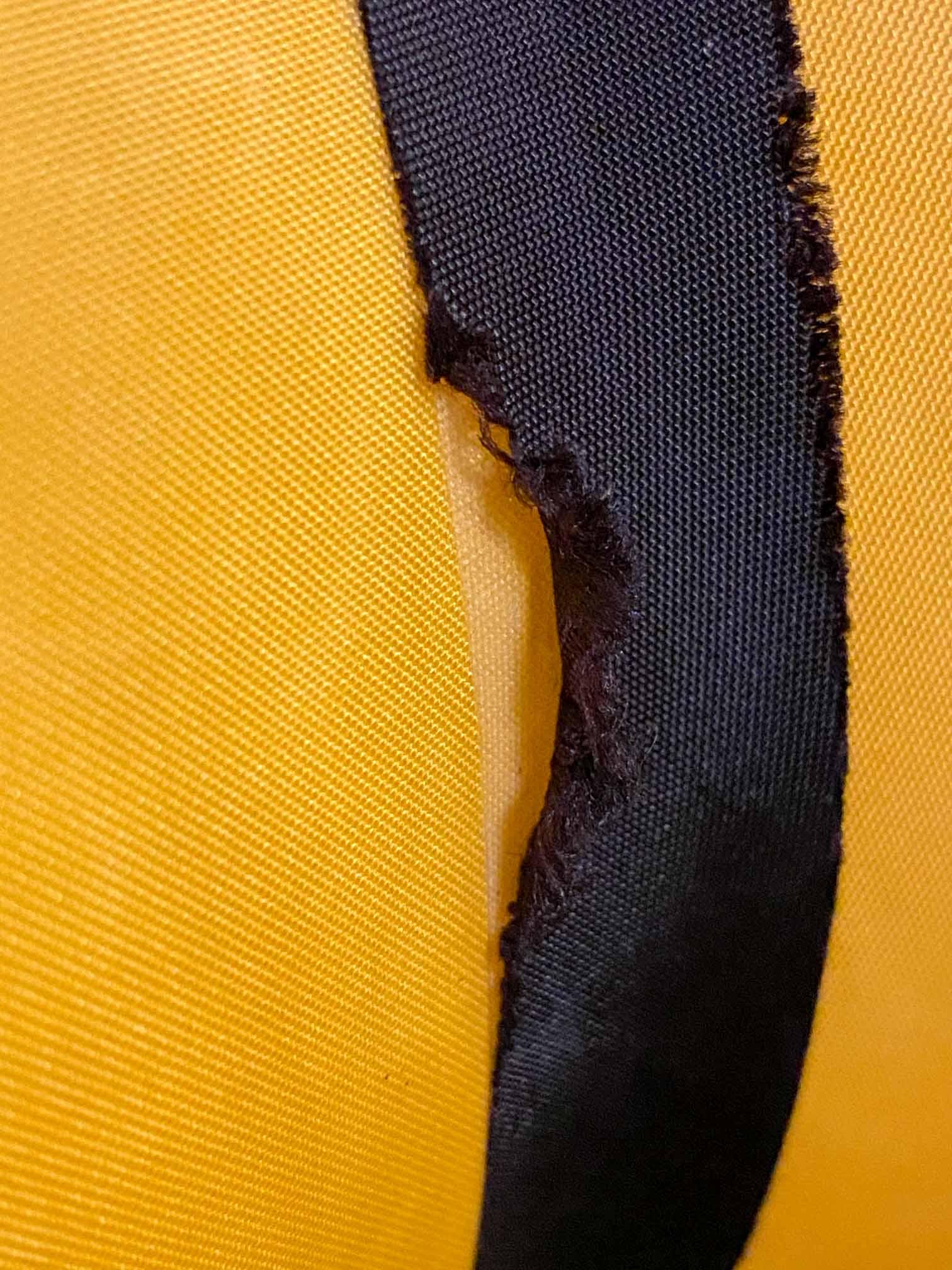

If you don’t coat the outside of the seam strips with a sealant, then after using your packraft for some time you may notice that the edges of the seam strips have begun to fray, especially in high-wear areas such as the bottom of the packraft or where your shoes rub against the seams in the forward area of the cockpit.

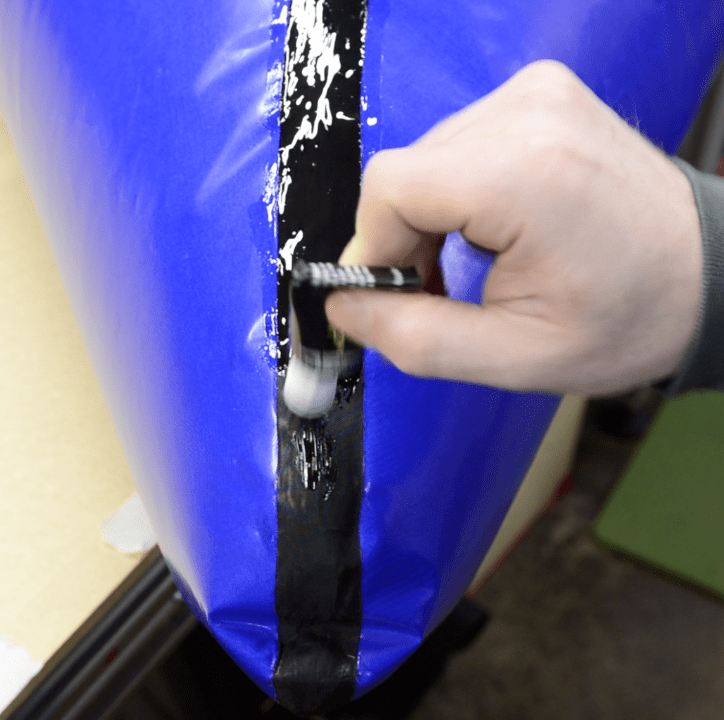

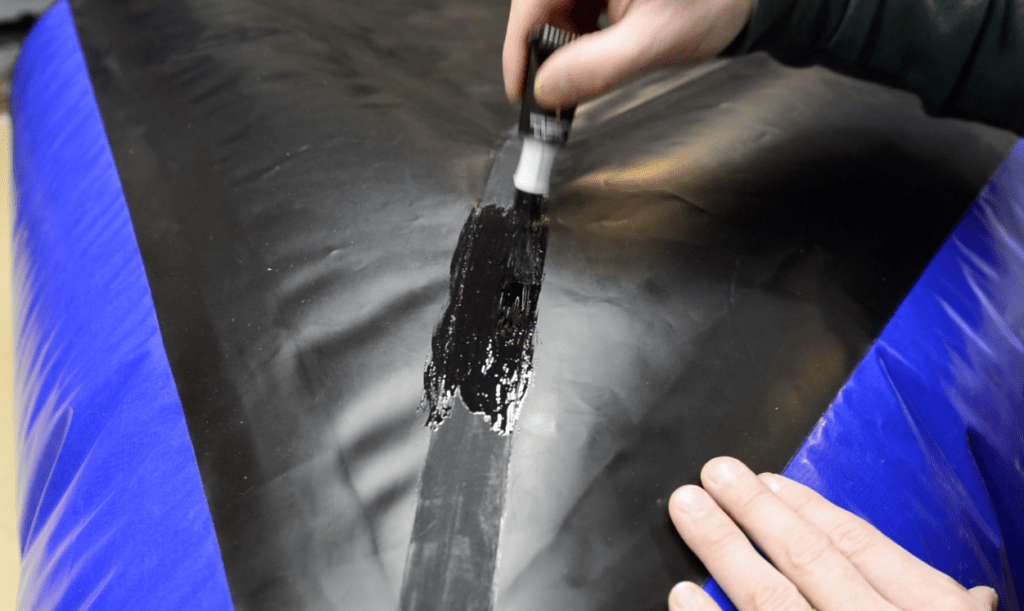

To prevent this from happening in the first place, or to prevent it from getting worse over time, apply Seam Grip+WP or Aquaseal or Aquasure to the outside of the seam strips (never use Seam Grip+SIL silicone tent sealant on a packraft).

I usually coat just the part of the seam strips that are below the waterline, but some people have found that this is not enough, so my current recommendation is to coat all of the seam strips.

This is most easily done with the packraft inflated – you can do the top and bottom separately, allowing time for it to dry before flipping it over, or you can apply sealant to the inside of the cockpit and the top of the seam strips and then flip it over, propping it up on something (such as a couple of cardboard boxes) so the seam strips remain elevated above your work surface.

Tips:

- It’s easier to apply sealant to an inflated packraft.

- Make sure the fabric is clean and free of soap or tape residue before applying the sealant.

- Spread the sealant a few mm past the edges of the seam strips (it won’t darken the fabric on the outside of the packraft).

- You can also apply the sealant to the reinforcing strips around the inside of the cockpit, if you like. This will prevent them from soaking up any water.

- After applying sealant to the seam strips (and optionally, the reinforcing strips) where they attach to the floor at the inside of the cockpit, elevate the packraft and/or wedge something between the tube and floor fabric to keep them apart so they don’t get glued together.

- The sealant will feel dry and will be functional after about eight hours, but it takes several days for the sealant to cure to the point where it won’t stick to itself. If you allow the sealant to cure completely before use (leaving your packraft inflated for several days) then dust and debris won’t stick to it and it will have a nice glossy surface – at least until you scuff it up. If you need to roll up the packraft before the sealant can cure completely, rub some talcum powder on the surface of the sealant so it won’t stick to itself.

Assembly Steps

- Iron Preparation & Heat Sealing Practice

- Separate Fabric Pieces

- Mark & Label Fabric Pieces

- Inflation Bag Assembly

- Seat Assembly

- Backrest Assembly

- Packraft Assembly:

- Tubes 3R & 3L

- Tubes 2R & 2L

- Tube 1

- Airtight Zipper (optional)

- Tubes 4R & 4L

- Seat Attachment Point

- Inflation Valve

- Rear Center Seam

- Inflate & Test for Leaks

- Apply Sealant to Outside Seams

- Attachment Points (a.k.a. “tie-downs”)

- Top-Up Valve (optional)

- Spray Deck Assembly (optional)

- Spray Skirt Assembly (optional)

Questions? Leave a comment below!

0 Comments